2nd Generation Layered Silicates

Clay minerals are the weathering product of primary rocks and therefore represent the most common minerals on earth’s surface. A high adsorption capability, cation exchange capacity, catalytical activity, good waterproofing effect and outstanding rheological characteristic render clay minerals one of the most important industrial minerals. Although natural clays are budget-priced, their potential application is severely restricted accessorial binders inhomogeneous charge density, turbostratic disorder and limited lateral extent (< 200 nm). Therefore, we concentrate on synthetic layered silicates as versatile inorganic base materials for technical applications.

Synthesis

Melt-synthesis paves the way to synthetic layered silicates with enhanced characteristics. Applying classic solid state methods as well as highly scalable methods aiming at industrial applications, we gain control over the chemical composition, charge density and thereby the swelling and delamination capability. Moreover, the crystallite size and disorder are improved without limiting the intracrystalline reactivity. In contrast to natural clay minerals, transition metal containing layered silicates offer interesting material properties like redox activity, electrical conductivity and magnetic features due to the multivalent cations in the octahedral sheets.

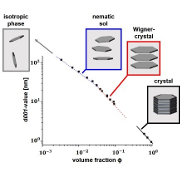

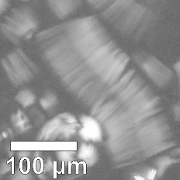

Swelling and Delamination

Melt synthesis allows for a quantum leap concerning the uniformity of its intra-crystalline reactivity and yields a material that spontaneously delaminates quantitatively in water. Starting from a dry powder the separation of neighbouring silicate layers in lamellar liquid crystals can be continuously adjusted up to 100 nm by the added water volume. Thus, kinetical barriers for the functionalisation by ion exchange (even with bigger molecules or nanoparticles) vanish.

With this material, we are able to conduct fundamental studies on the swelling of layered silicates. A deeper understanding of the swelling process enables us to conduct the osmotic delamination of layered silicates with higher charge density. These exhibit a higher lateral extent and therefore pave the way to high-aspect-filler materials for e.g. the encapsulation of optoelectronical components. Furthermore, the expansion of the swelling studies to organic solvent/water mixtures can be of central interest for compound systems as processable suspension environments are extended to hydrophobic polymer matrices and surface modificators.

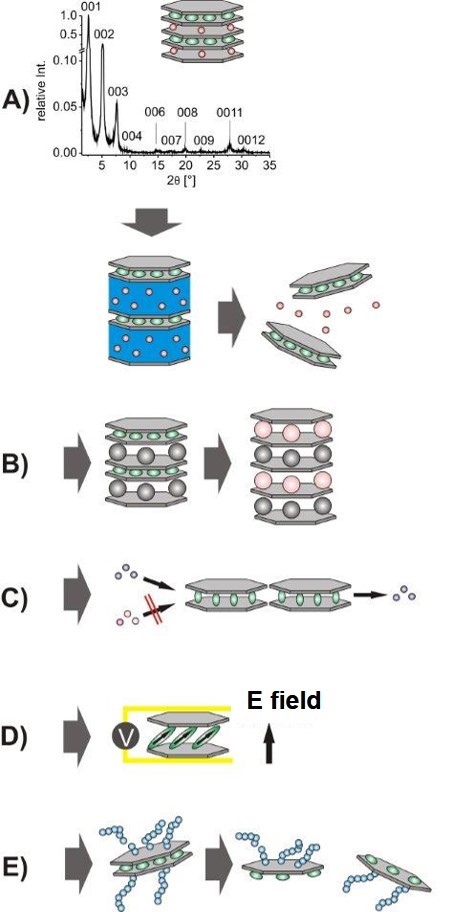

Intercalation, Double Stacks and Janus-like Platelets

Based on the high-quality synthetic hectorite 1-dimensional ordered hetero-structures can be produced by partial ion exchange (A). These materials are characterized by a stringent alternation of two differently occupied interlayer spaces that, subsequently, can be targeted selectively. Physically separated confined nano-reaction spaces with no mass transport in between but electically coupled are obtained by intercalation with two species of cationic colloids (B).

Alternatively, hetero-structures can quantitatively be delaminated to double stacks of ca. 5 nm thickness with no mas transport in between, but encapsulating a functional interlayer between two silicate layers. These interlayers exhibit e.g. optical anisotropy, polarizability or microporosity.